STRAIN GAUGE

At M-TEK, we specialize in the design and implementation of systems utilizing strain gauges for a wide array of applications.

Strain gauges, integral to our solutions, convert mechanical deformation into electrical signals, providing unparalleled accuracy in monitoring and analyzing the behavior of diverse structures and materials under different conditions.

Typical Applications include:

- Bespoke Load Testing Systems: Our expertise lies in creating load testing systems that assess the performance and safety of machinery, vehicles, and components across various industries. These systems are meticulously designed to meet specific requirements and comply with industry standards.

- Advanced Material Testing Capabilities: Leveraging our proficiency in strain gauge technology, we develop cutting-edge solutions for characterizing the mechanical properties of materials. Our systems facilitate comprehensive material testing for metals, composites, and polymers, empowering clients to optimize material selection and design processes.

- Innovative Aerospace and Automotive Solutions: Our engineering prowess extends to aerospace and automotive applications, where we design and implement strain gauge-based systems for testing aircraft structures, vehicle chassis, and components. These solutions ensure optimal performance, reliability, and safety in demanding environments.

- Tailored Industrial Process Control Systems: We integrate strain gauge technology into manufacturing equipment and processes, offering bespoke solutions for industrial process control. Our systems enable real-time monitoring, fault detection, and performance optimization, enhancing overall efficiency and productivity.

In essence, M-TEK offers comprehensive solutions harnessing the versatility and precision of strain gauges across a multitude of industries and applications.

With our expertise, clients can expect tailored solutions that meet their unique requirements and drive innovation in their respective fields.

One extreme example of where we have successfully developed and used this technology was for a research project that we accomplished the following requirements:

- Simultaneous sampling of 63 Strain, gauges in X.Y and Z directions

- Each Strain gauge was sampled with 24 bit Analog to Digital converter per strain gauge split into 16bit (65536 levels) for values and 8bit for offset at a 10kHz sample rate.

- at 125MHz, which gives a time resolution of 8ns.

- Unit was fully sealed and could survive long term in harsh conditions

- X6 of above mentioned units could be installed next to each other ending with 378 strain gauges across a road

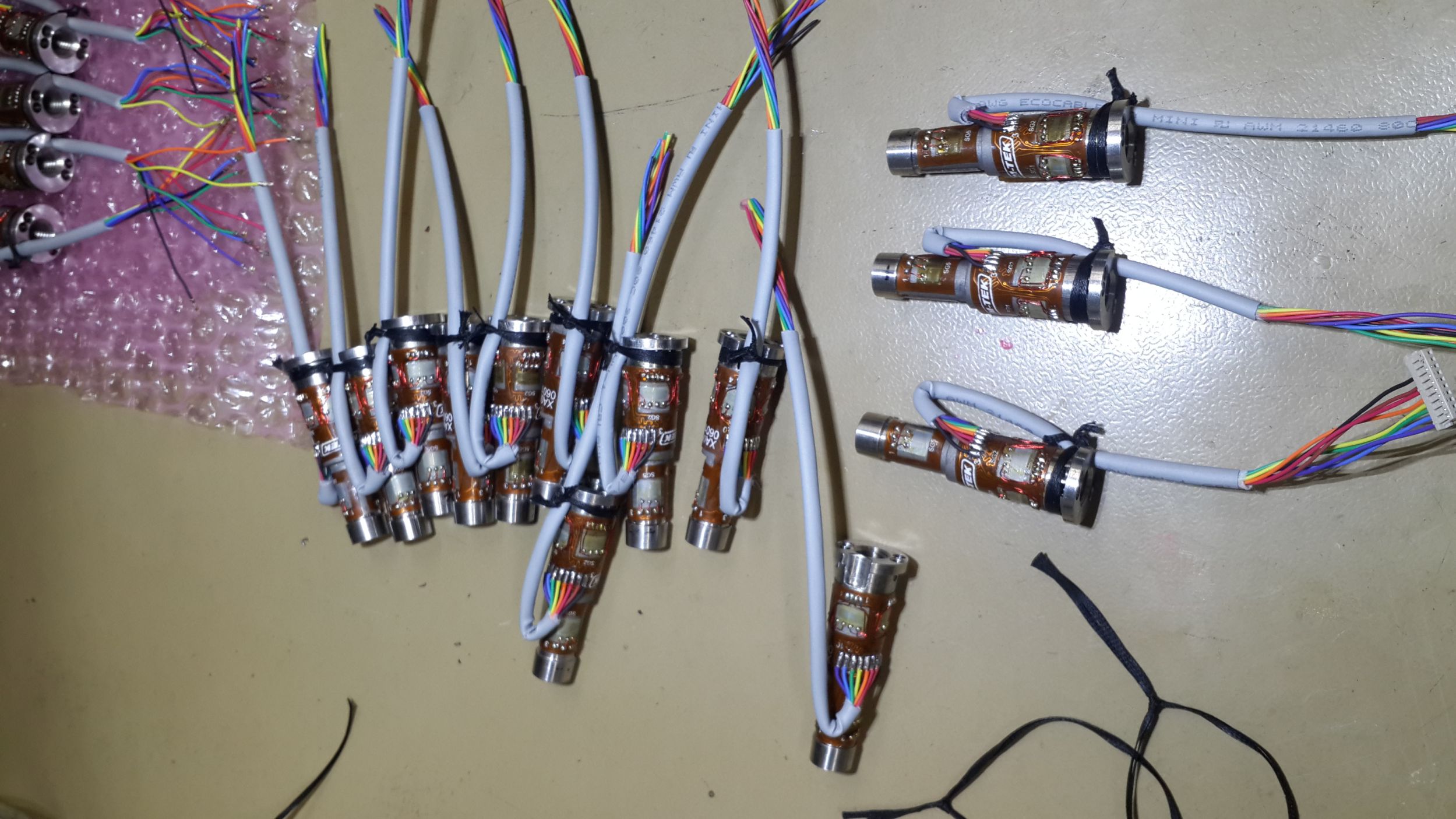

Strain Gauge photos:

Please contact M-Tek for more information by clicking Request Information below.